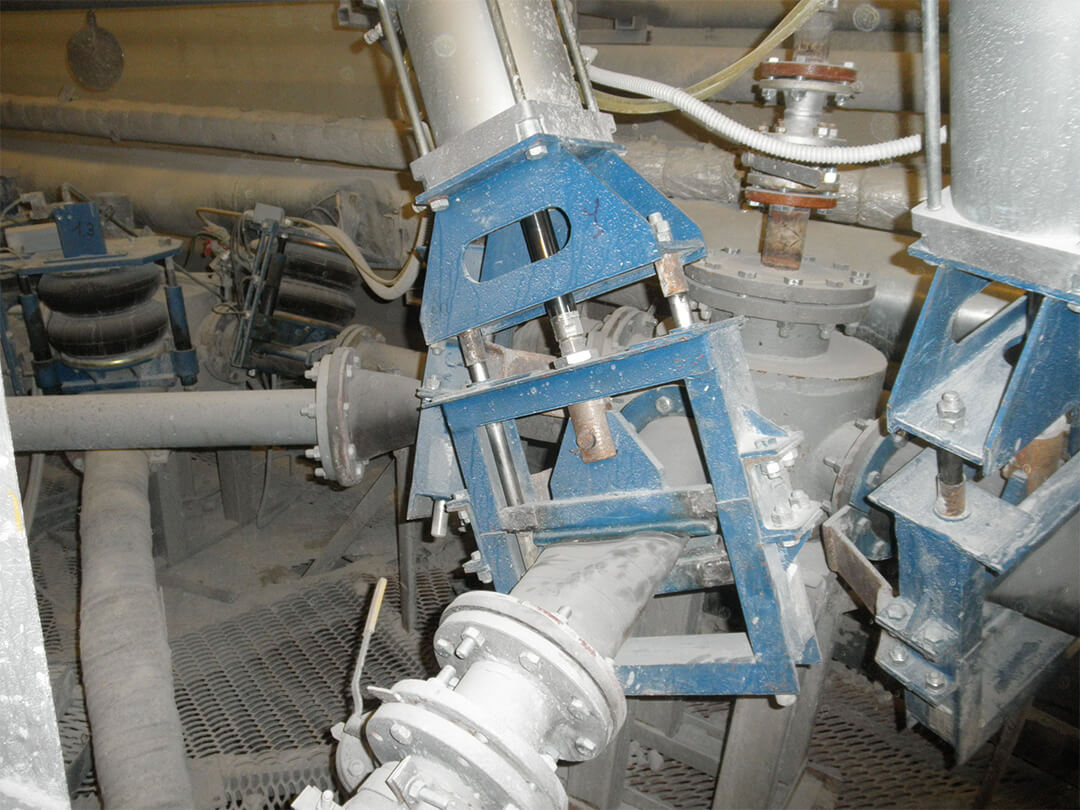

Clamping devices are the most common type of shut-off and control valves installed on pipelines, units and other systems.

This type of devices is designed for control (shut-off/regulation) of working media flows (liquid, gaseous, gas-liquid, powdery, suspensions, etc.) by changing the cross-sectional area.

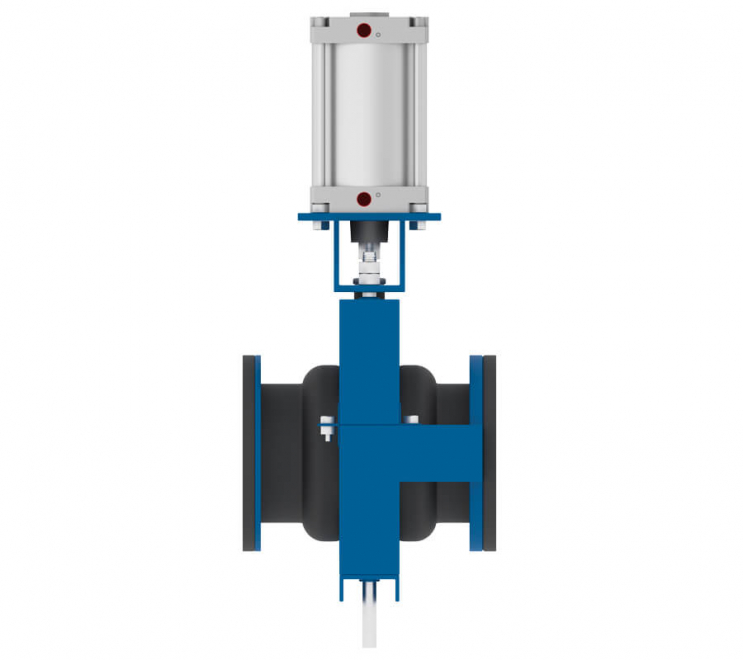

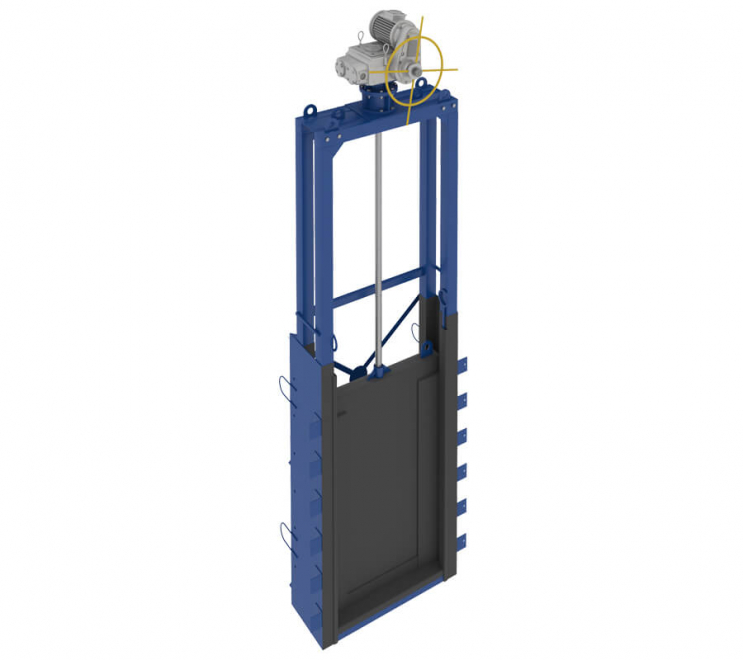

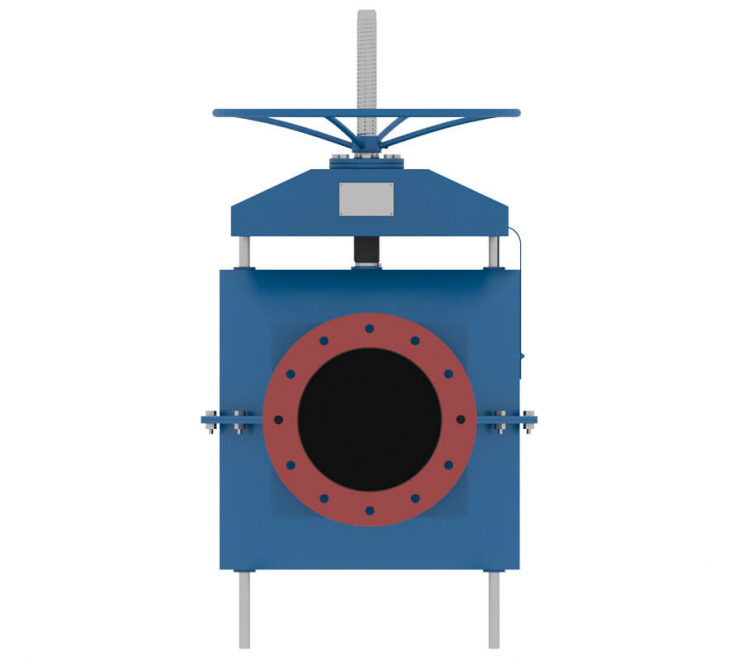

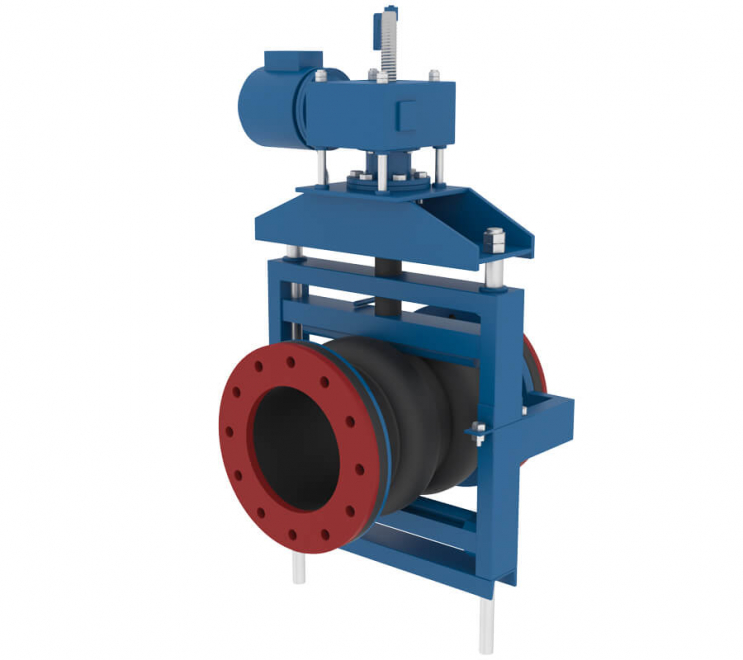

Compression devices are manufactured with a range of internal diameter from 50 to 800 mm, designed for working pressure up to 1.6 MPa.

The connection of clamping devices to the pipeline is flanged (steel integrated rubberised flanges), which ensures reliable tightness of jointed parts without the use of additional gaskets.

The design feature of the "New Technologies" LLC series clamping devices is the presence of a replaceable elastic rubber valve.

Advantages of using the squeezing devices produced by "New Technologies" LLC:

- absence of contact of transported working medium with the body of the gate valve;

- reduction of accident rate due to the use of special "wear control" system;

- longer service life.

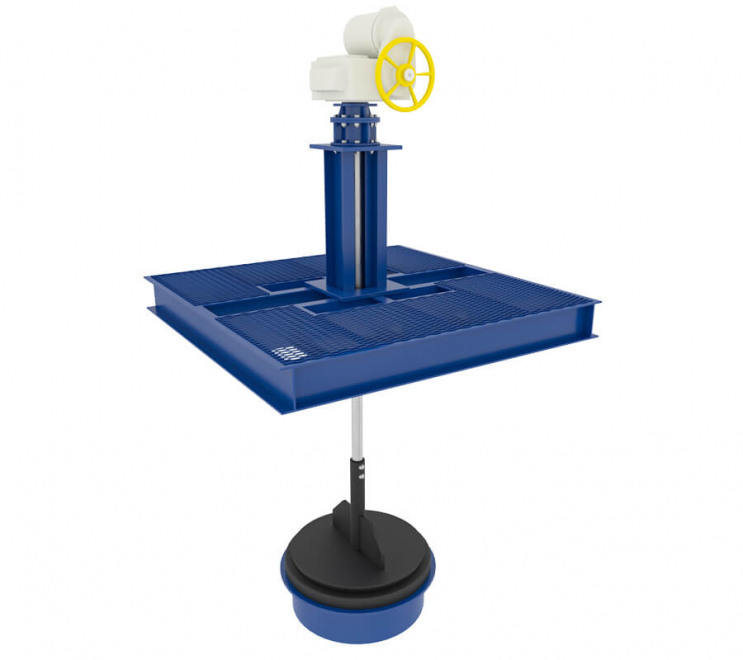

Depending on operating conditions, the devices are additionally equipped with a special working element - "ears", which allows to prevent valve collapse, to forcefully open the valve (in case of vacuum formation in the system).